Solar energy applications are not just the solar electric panels that convert sunlight to electricity, or the majestic large, spinning, wind turbines we see on the great plains or in offshore clusters. Solar applications also include the use of biomass…..organic materials grown and then processed into fuel or useful products.

Here is what the National Renewable Energy Laboratory [NREL] has to say about biomass applications:

- Biofuels — Converting biomass into liquid fuels for transportation

- Biopower — Burning biomass directly, or converting it into gaseous or liquid fuels that burn more efficiently, to generate electricity

- Bioproducts — Converting biomass into chemicals for making plastics and other products that typically are made from petroleum

Biofuels can be used to supplement our energy sources, replace existing petrochemical energy sources, reduce dependence on foreign sources of energy, and reduce the environmental impact/greenhouse gas emissions of petrochemical energy use.

Every time the price of a barrel of oil goes up a dollar, it costs the Navy $31 million in extra fuel costs. The U.S. military is very interested in alternative fuels — in particular, the wood-based biofuels being researched and produced at the University of Maine. Check out this amazing process.

Professor Clayton Wheeler of U of Maine holding a bottle of biofuel made from wood materials. This biofuel can be used as is as a substitute for heating oil or refined a bit more for use as a premium transportation fuel/jet fuel.

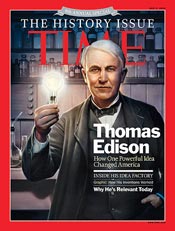

It is fascinating to remember Thomas Edison experimented with biomass back in the late 1920s, trying to find common plant materials that could be processed to become a viable substitute for rubber. In his painstaking years of work, Edison and his staff evaluated about 17,000 candidate plant species, to develop a giant cross-bred goldenrod plant that could grow as tall as 12 feet; and whose structure contained about 12% rubber. In 1927, Edison, Henry Ford, and Harvey Firestone formed the Edison Botanic Research Corporation of Fort Myers. Plants were collected in Florida and throughout the southern United States by field collectors. Plants were grown under controlled conditions in Florida and at Edison’s laboratories in West Orange, New Jersey.

Edison in Fort Myers in 1931, along with his giant goldenrod plant, later named after him, Solidago edisoniana.

The plant processing equipment Edison used in his West Orange Chemistry Lab to facilitate the extraction of latex rubber from his goldenrod and other candidate plants.

Editor’s Deep Dive:

- http://www.nrel.gov/learning/

re_biomass.html - http://www.ucsusa.org/clean_

energy/our-energy-choices/ renewable-energy/how-biomass- energy-works.html - http://www.eia.gov/kids/

energy.cfm?page=biomass_home- basics - http://www.biofuelsjournal.

com/articles/University_of_ Maine_Researchers_Work_to_ Develop_Biomass_Jet_Fuel_For_ U_S__Military_-122983.html

Thomas Edison said … “I’d put my money on the sun and solar energy. What a source of power! I hope we don’t have to wait until oil and coal run out before we tackle that. I wish I had more years left.”

Thomas Edison said … “I’d put my money on the sun and solar energy. What a source of power! I hope we don’t have to wait until oil and coal run out before we tackle that. I wish I had more years left.”

Time ® is a registered trademark of Time Inc.

Biomass conversion is the big energy resource for us. Biomass waste can convert into useful fuel with the help of briquetting machine which are invented by briquette press manufacturers India and this is the big invention for industries.

The conversion of biomass waste to useful eco-friendly fuel briquettes through briquetting plant can be helpful for environment and energy saving.

Biomass briquetting plant working as eco friendly resource and uses agriculture wastage materials as raw materials which are sulfur less and never spread pollution while burning. So due to renewable energy plant it never effect bad to atmosphere.

Your work is really good and I appreciate this information. I forever prefer to read quality and glad I found this thing in your post. Thank you for the comprehensive article.

Thanks for such a pleasant post. This post is loaded with lots of useful information. Keep it up.

Great information joy & hope and peace all is so nice advice for us , thanks for sharing it give us the first opportunity to visit this website along with you .

Thank you very much for this amazing post. I admire your inspiring and motivating works and I would love to read more of your great article.

Dyder International B.V. is based in Breukelen, Netherlands. The corner stone of the company has been laid in 2009; since then, with our zinc ingot suppliers we are soaring to new levels of success with each passing day.